Diesel Emissions Control Systems for Light and Heavy Duty Trucks

Understanding Modern Diesel Emissions Technology

Modern diesel emissions control systems represent sophisticated engineering solutions designed to meet stringent EPA regulations while maintaining the power and efficiency that makes diesel engines essential for heavy-duty applications. These systems work together as an integrated network to dramatically reduce harmful pollutants from diesel exhaust.

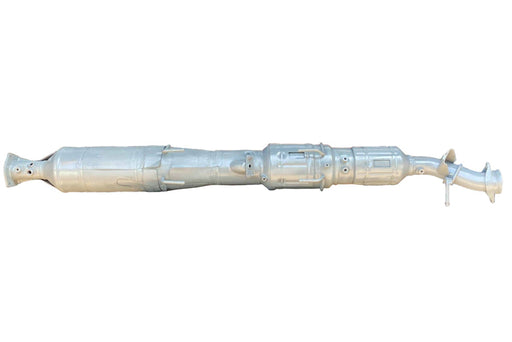

Diesel Particulate Filter (DPF) Systems

The diesel particulate filter serves as the primary defense against particulate matter emissions in light duty diesel trucks including the Ford F250 and F350, Chevrolet and GMC 2500 and 3500 series, and Ram 2500 and 3500 models. DPF systems capture microscopic soot particles, storing them until the system initiates a regeneration cycle that burns off accumulated particulates at extremely high temperatures.

Light duty diesel trucks typically feature wall-flow DPF designs that force exhaust gases through porous ceramic walls, trapping particles while allowing clean gases to pass through. These systems require periodic active regeneration cycles, especially in stop-and-go driving conditions common with work trucks and daily drivers.

Diesel Oxidation Catalyst (DOC) Technology

Positioned upstream of the DPF, the diesel oxidation catalyst functions as the first line of treatment for diesel exhaust gases. DOC systems convert harmful carbon monoxide and unburned hydrocarbons into less harmful carbon dioxide and water vapor through catalytic oxidation processes.

For pickup trucks like the F250, F350, Ram 2500, Ram 3500, and Chevy/GMC 2500/3500 series, DOC systems also play a crucial role in supporting DPF regeneration by increasing exhaust temperatures and creating the optimal conditions for particulate burnoff.

Selective Catalytic Reduction (SCR) Systems

SCR technology represents the most advanced approach to reducing nitrogen oxide (NOx) emissions in modern diesel engines. These systems inject diesel exhaust fluid (DEF) into the exhaust stream, where it reacts with NOx compounds over a specialized catalyst to produce harmless nitrogen and water vapor.

Light duty diesel trucks equipped with SCR systems can achieve NOx reduction rates exceeding 90%, making them compliant with the most stringent emissions standards while maintaining excellent fuel economy and performance characteristics that diesel truck owners demand.

Medium and Heavy Duty Applications

While light duty pickups represent a significant portion of the diesel market, medium duty trucks and heavy duty commercial vehicles utilize similar but more robust emissions control technologies. Class 6-8 trucks often feature larger capacity DPF systems, multiple DOC stages, and high-efficiency SCR systems designed for continuous operation under demanding conditions.

Integrated System Performance

Modern diesel emissions systems work synergistically, with each component supporting the others to achieve optimal performance. The DOC prepares exhaust gases for DPF treatment while providing thermal management, the DPF captures particulates, and the SCR system eliminates NOx compounds, creating a comprehensive emissions control solution that maintains diesel engines' reputation for durability, efficiency, and power delivery.